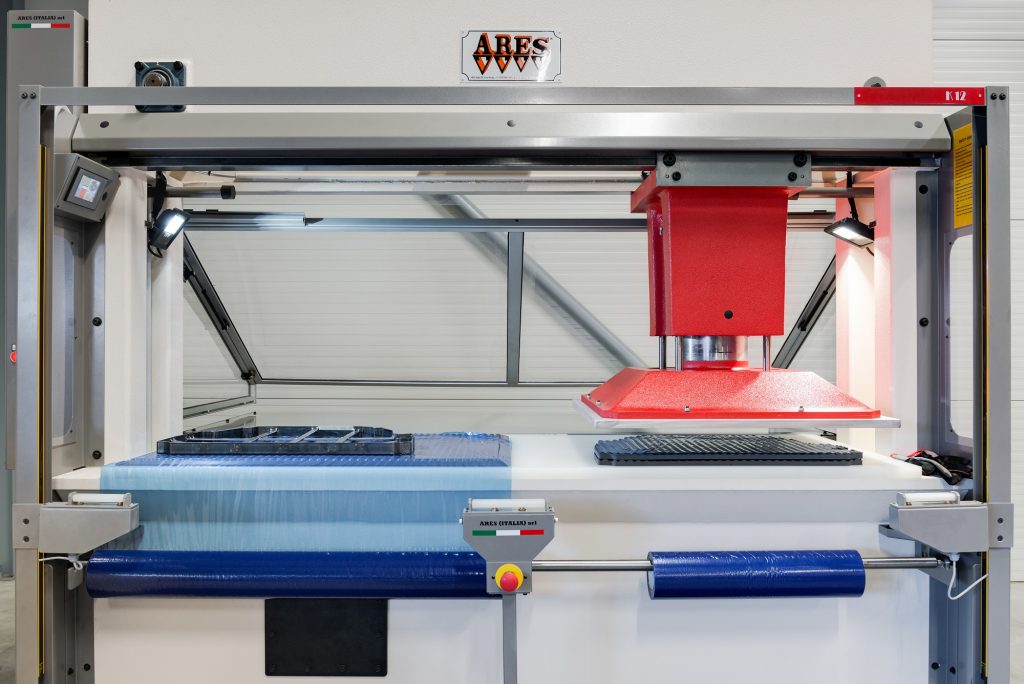

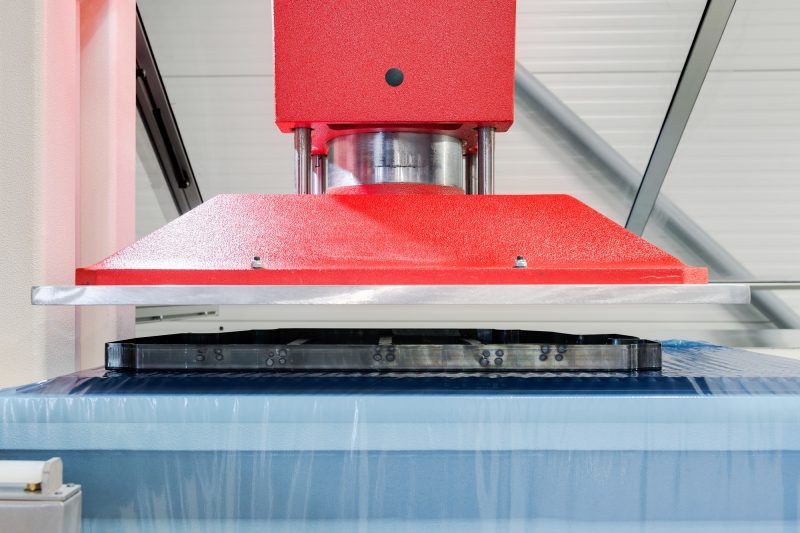

Punching in Soft Materials

We primarily use knife punches to punch various types of soft materials such as polyurethane, rubber, plastic and gasket material. We can also help you with tool production as we have extensive experience with it.

Tool costs are also an important factor. Because the tools are simple, the tools can be cost-effective compared to the costs of water cutting, when the unit cost is very high.

A versatile process that is cost effective

Producing punching tools is a relatively low cost, which is why punching is suitable for both small and large series. Products that today are produced through advanced cutting could be manufactured both easier and faster by punching.

Punching is ideally suited for producing gaskets. Of the requests we get, punching gaskets is the most common and it’s easy to understand. Many different materials can be punched, below is a selection.

Examples of materials that can be punched

- Natural rubber

- EPDM

- Silicone

- Cellular rubber

- Polyester foam

- Polyethylene

- Polypropylene

Packaging

Gaskets are used in several different types of products. Today, our main clientele is found in the electronics industry. We can supply basically anything when it comes to gaskets, for example we have produced gaskets for forestry machines, toilets, water pipes and compressors for air and oil.

Environment and recycling

Pur Partner recycles all our waste from the punching, and all customers can send used products back to us. We mix 90% old material with 10% new and cast new products that are sold in our sister company Rosén Innovation AB.

We think it’s environmentally friendly thinking.