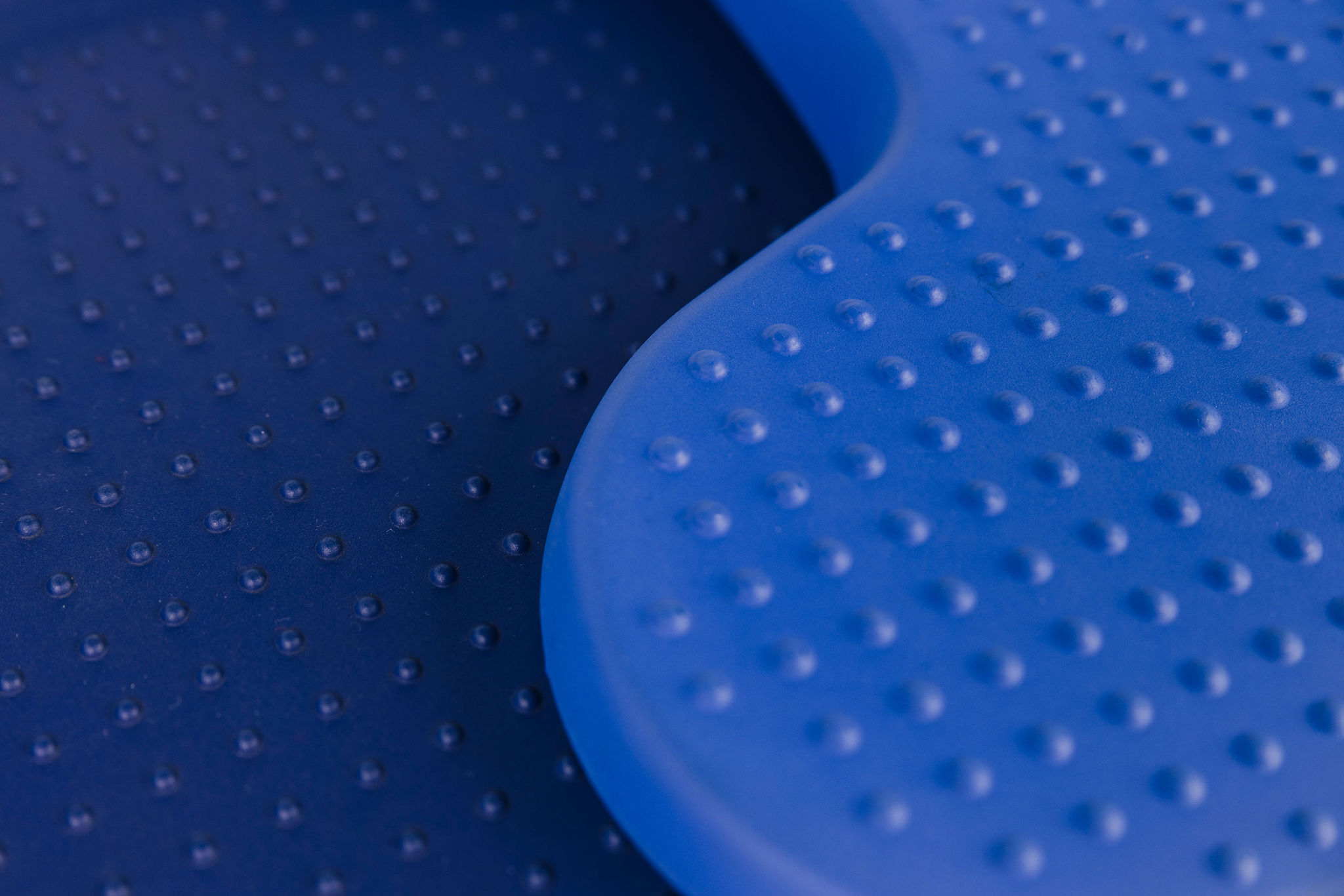

Polyurethane foam

If the polyurethane foams, it contains a so-called blowing agent, which can be water or some other type of propellant, which causes the material to expand and form a polyurethane foam that can be skinned or open-celled.

With the help of other additives, hardness, density and colour, among other things, can be controlled. If no blowing agent is used, the polyurethane becomes solid and is then often called elastomers or urethane rubber.

A versatile material – with the help of additives

Polyurethanes are a polymer, and like all plastics, polymers are made from diisocyanates that are allowed to react with a selection of polyols. Depending on the desired end product, different chemical formulations may contain different ingredients, such as blowing agents, catalysts, antistats, pigments and possibly flame retardants.

Polyurethane system consists of polyol and isocyanate in liquid form

When molding a polyurethane system, the base part consists of polyol and isocyanate in liquid form. The polyol can be based on polyether or polyester, the isocyanate is usually of the MDI type. When these two components are mixed with the help of modern machines, a reaction takes place – and the polyurethane is created.

The big advantage of this type of method – so-called reaction molding or RIM (reaction injection molding) – is that you can control the reaction of the polyurethane directly in the mold with the help of various additives.